How Much Vacuum Does a Brake Booster Need?

The braking system is one of the most critical components when it comes to vehicle safety. A key part of this system is the brake booster, which amplifies the force applied by the driver on the brake pedal, making it easier to stop the vehicle. However, for a brake booster to function properly, it requires a specific amount of vacuum pressure.

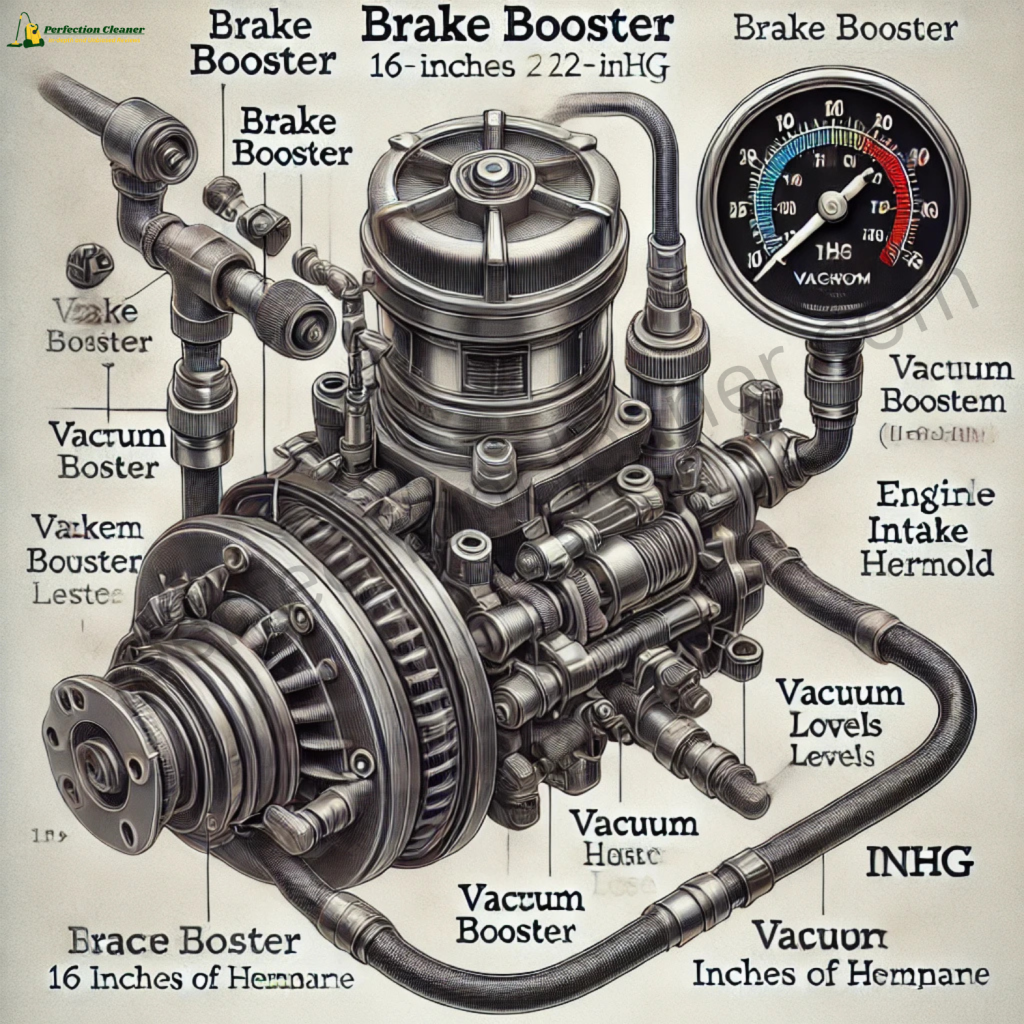

The brake booster is an essential component of modern automotive braking systems, designed to enhance the driver’s ability to stop the vehicle with minimal effort. The brake booster amplifies the force applied to the brake pedal by utilising vacuum pressure, making braking more efficient and responsive. But how much vacuum does a brake booster need to function properly? This article delves into the mechanics of brake boosters, the role of vacuum pressure, and the factors that determine the optimal vacuum level for effective braking.

Understanding the Brake Booster

What is a Brake Booster?

A brake booster, also known as a vacuum booster, is a device that uses vacuum pressure to assist in braking. It is typically located between the brake pedal and the master cylinder. When the driver presses the brake pedal, the brake booster uses vacuum pressure to multiply the force, reducing the effort required to stop the vehicle.

Before diving into the specifics of vacuum requirements, it’s important to understand what a brake booster is and how it works. A brake booster, also known as a vacuum servo, is a device that uses vacuum pressure to assist the driver in applying the brakes. It is typically located between the brake pedal and the master cylinder.

When the driver presses the brake pedal, the brake booster uses the vacuum to multiply the force applied, reducing the physical effort required to stop the vehicle. This is particularly important in modern vehicles, which are heavier and require more braking force than older models.

The Role of Vacuum in Brake Boosters

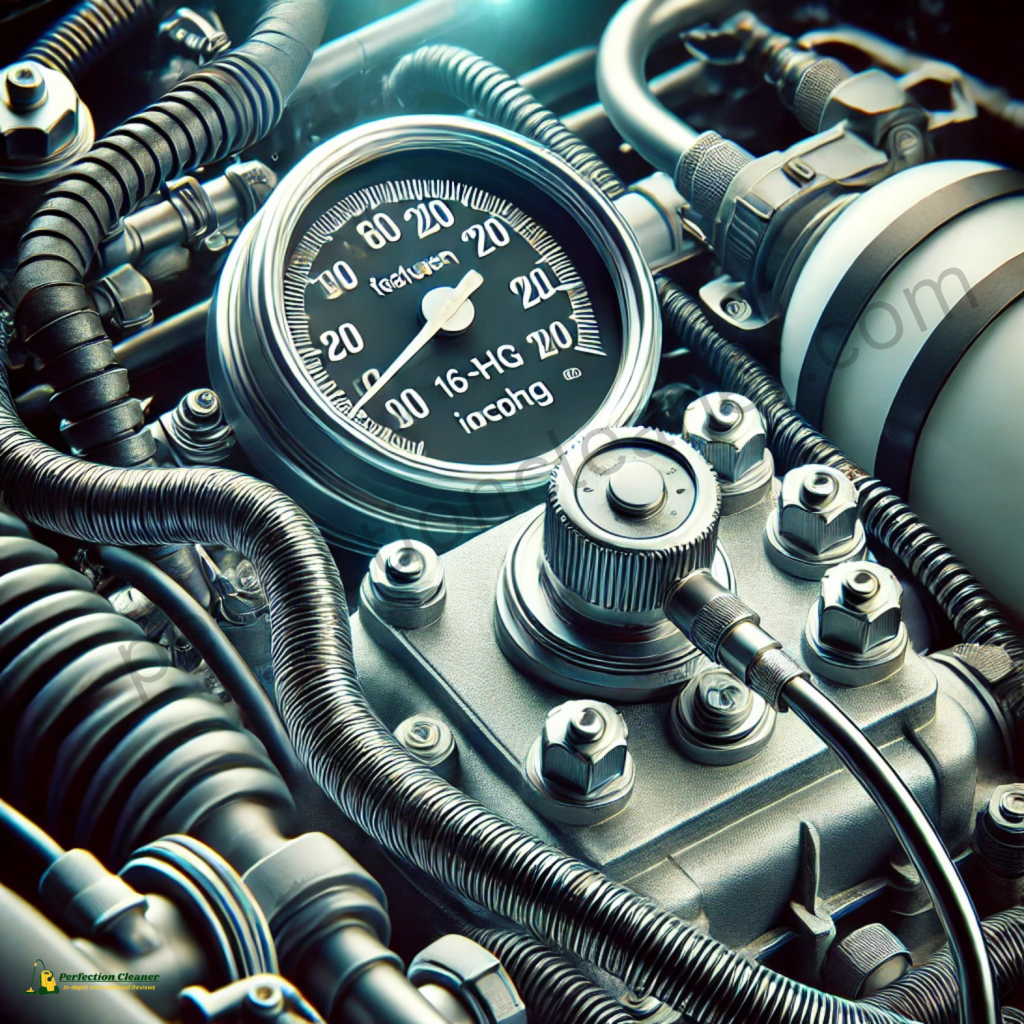

The vacuum is the key to the brake booster’s operation. Most brake boosters rely on engine vacuum, which is generated by the internal combustion engine. As the engine runs, it creates a vacuum in the intake manifold, which is then used to power the brake booster.

The vacuum is stored in a vacuum reservoir or directly supplied to the brake booster. When the brake pedal is pressed, the vacuum is applied to one side of a diaphragm inside the booster, while atmospheric pressure is applied to the other side. This pressure difference creates the force needed to assist in braking.

How Much Vacuum Does a Brake Booster Need?

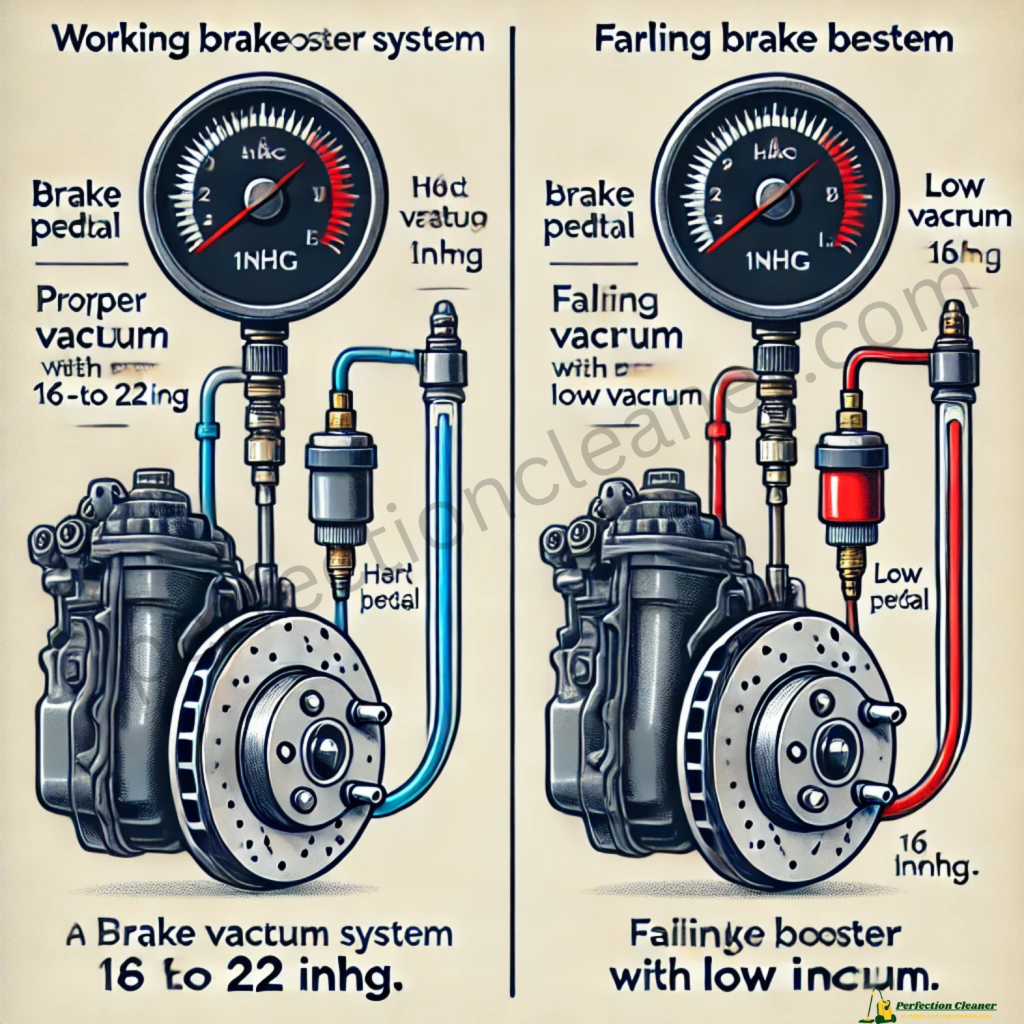

The amount of vacuum required for a brake booster to function effectively typically ranges between 18 and 22 inches of mercury (inHg). This is the standard vacuum level for most passenger vehicles. However, the exact requirement can vary depending on the design of the brake booster, the size of the vehicle, and the type of braking system.

- Minimum Vacuum Requirement:

Most brake boosters require a minimum of 18 inHg to operate effectively. If the vacuum level drops below this threshold, the booster may not provide sufficient assistance, making the brake pedal feel harder to press and reducing braking efficiency. - Optimal Vacuum Range:

The optimal vacuum range for a brake booster is between 18 and 22 inHg. At this level, the booster can provide the necessary force multiplication without overloading the system. - Maximum Vacuum Limit:

While higher vacuum levels can theoretically provide more assistance, most brake boosters are designed to operate within the 18-22 inHg range. Exceeding this range can cause the diaphragm to overextend, potentially damaging the booster.

Factors Affecting Vacuum Requirements

Several factors can influence the amount of vacuum a brake booster needs to function properly. These include:

- Engine Type:

The type of engine in the vehicle plays a significant role in determining the available vacuum. Gasoline engines typically generate more vacuum than diesel engines, which may require an additional vacuum pump to meet the brake booster’s needs. - Vehicle Size and Weight:

Larger and heavier vehicles require more braking force, which in turn requires a higher vacuum level. For example, a heavy-duty truck may need a vacuum level closer to 22 inHg, while a smaller passenger car may operate effectively at 18 inHg. - Brake Booster Design:

Different brake boosters are designed to operate at different vacuum levels. Some boosters are more efficient and can provide adequate assistance at lower vacuum levels, while others may require higher vacuum levels to function properly. - Altitude and Environmental Conditions:

Atmospheric pressure decreases at higher altitudes, which can affect the performance of the brake booster. Vehicles operating at high altitudes may require adjustments to maintain the necessary vacuum level. - Vacuum Leaks:

Any leaks in the vacuum system can reduce the available vacuum, making it harder for the brake booster to function. Regular maintenance and inspection of the vacuum lines and connections are essential to ensure optimal performance.

Testing Vacuum Levels in a Brake Booster

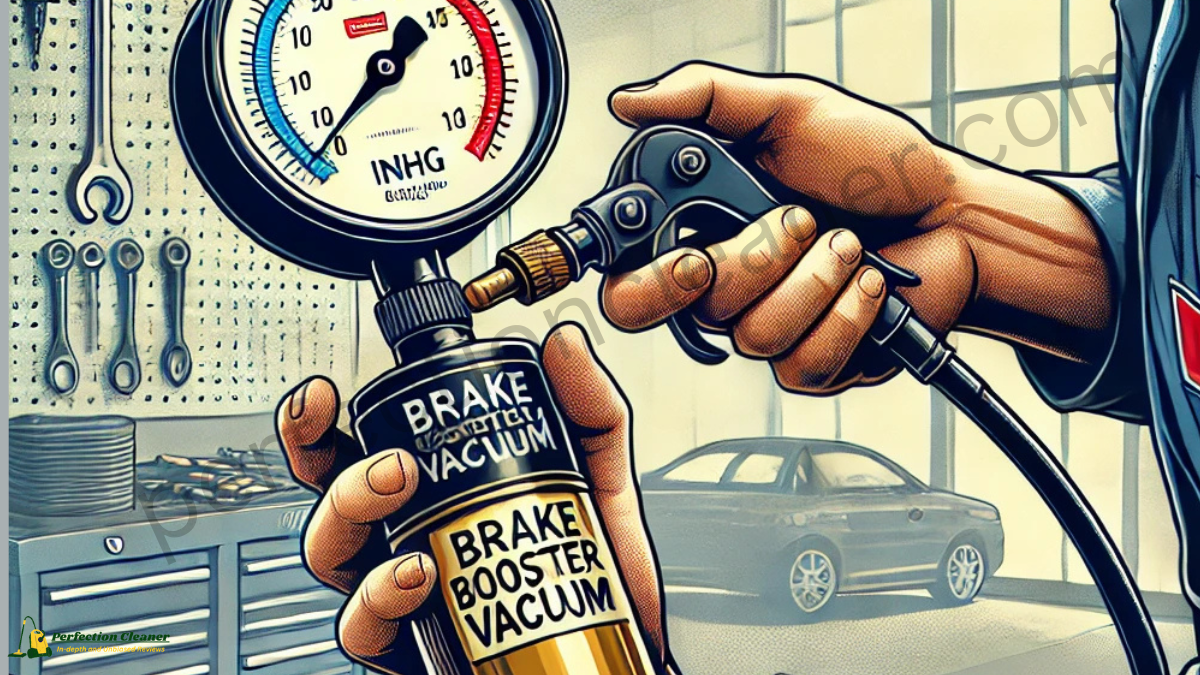

To ensure that the brake booster is receiving the correct amount of vacuum, it’s important to test the vacuum levels periodically. This can be done using a vacuum gauge, which measures the vacuum pressure in the system.

- Locate the Vacuum Line:

The vacuum line connects the brake booster to the engine’s intake manifold. Disconnect the line and attach the vacuum gauge. - Start the Engine:

With the engine running, observe the vacuum gauge. The reading should be within the 18-22 inHg range. - Check for Consistency:

The vacuum level should remain consistent when the engine is idling. If the vacuum fluctuates or drops below the minimum threshold, there may be a problem with the vacuum system. - Inspect for Leaks:

If the vacuum level is low, inspect the vacuum lines and connections for leaks. Replace any damaged or worn components as needed.

Common Issues Related to Vacuum in Brake Boosters

- Hard Brake Pedal:

A hard brake pedal is often a sign of insufficient vacuum. This can be caused by a vacuum leak, a faulty vacuum pump, or a problem with the engine’s vacuum generation. - Reduced Braking Performance:

If the brake booster is not receiving enough vacuum, the braking performance may be reduced, making it harder to stop the vehicle. - Hissing Noise:

A hissing noise when pressing the brake pedal is a common symptom of a vacuum leak. This noise is caused by air entering the vacuum system through a damaged or loose connection. - Check Engine Light:

In some vehicles, a problem with the vacuum system can trigger the check engine light. This is often accompanied by a diagnostic trouble code related to the brake booster or vacuum system.

Maintaining the Vacuum System

Proper maintenance of the vacuum system is essential to ensure that the brake booster receives the correct amount of vacuum. Here are some tips for maintaining the vacuum system:

- Inspect Vacuum Lines:

Regularly inspect the vacuum lines for cracks, leaks, or damage. Replace any worn or damaged lines as needed. - Check the Vacuum Pump:

If your vehicle is equipped with a vacuum pump, ensure that it is functioning properly. A faulty pump can reduce the available vacuum and affect braking performance. - Monitor Engine Performance:

Since the engine generates the vacuum, any issues with engine performance can affect the vacuum level. Regular engine maintenance, including tune-ups and air filter replacements, can help maintain optimal vacuum levels. - Address Vacuum Leaks Promptly:

If you suspect a vacuum leak, address it promptly to prevent further damage to the brake booster or other components.

Conclusion

The brake booster is a critical component of the modern braking system, and its performance depends heavily on the availability of vacuum pressure. Most brake boosters require a vacuum level between 18 and 22 inHg to function effectively. Factors such as engine type, vehicle size, and environmental conditions can influence the vacuum requirements, so it’s important to ensure that the vacuum system is properly maintained and free of leaks.

By understanding the role of vacuum in brake boosters and taking steps to maintain the vacuum system, drivers can ensure that their vehicles remain safe and responsive on the road. Regular inspections and prompt repairs are key to keeping the brake booster operating at its best, providing the necessary assistance to stop the vehicle efficiently and safely.

This article provides a comprehensive overview of the vacuum requirements for brake boosters, offering valuable insights for vehicle owners and enthusiasts alike. Whether you’re troubleshooting a braking issue or simply looking to understand your vehicle better, knowing how much vacuum a brake booster needs is an essential piece of knowledge.

Find More about Vacuum Cleaner:

what is a good suction power for vacuum cleaner, Does Stanley Steemer Vacuum Before Cleaning, does roomba work on carpet, Which Miele Vacuum to Buy, What Vacuums Are Made in the USA, Are Riccar Vacuums Good, Why Does My Carpet Sound Crunchy After Vacuuming, can you vacuum wool rugs