Understanding Perfect Vacuum Hydraulics: Principles, Applications, and Future Prospects

Hydraulic systems have long been the backbone of industrial machinery, aerospace engineering, and automotive technologies, relying on pressurized fluids to transmit force. However, a lesser known yet revolutionary concept is emerging: perfect vacuum hydraulics. This innovative approach flips traditional hydraulics by leveraging the absence of pressure—rather than its presence—to generate motion and control. While a “perfect vacuum” remains a theoretical ideal, advancements in engineering are pushing systems closer to this limit, unlocking unique advantages in precision, safety, and efficiency. This article explores the principles behind vacuum-based hydraulics, their real-world applications, challenges, and their transformative potential across industries.

What is a perfect vacuum hydraulics

1. The Science of Perfect Vacuum Hydraulics

Defining a Perfect Vacuum

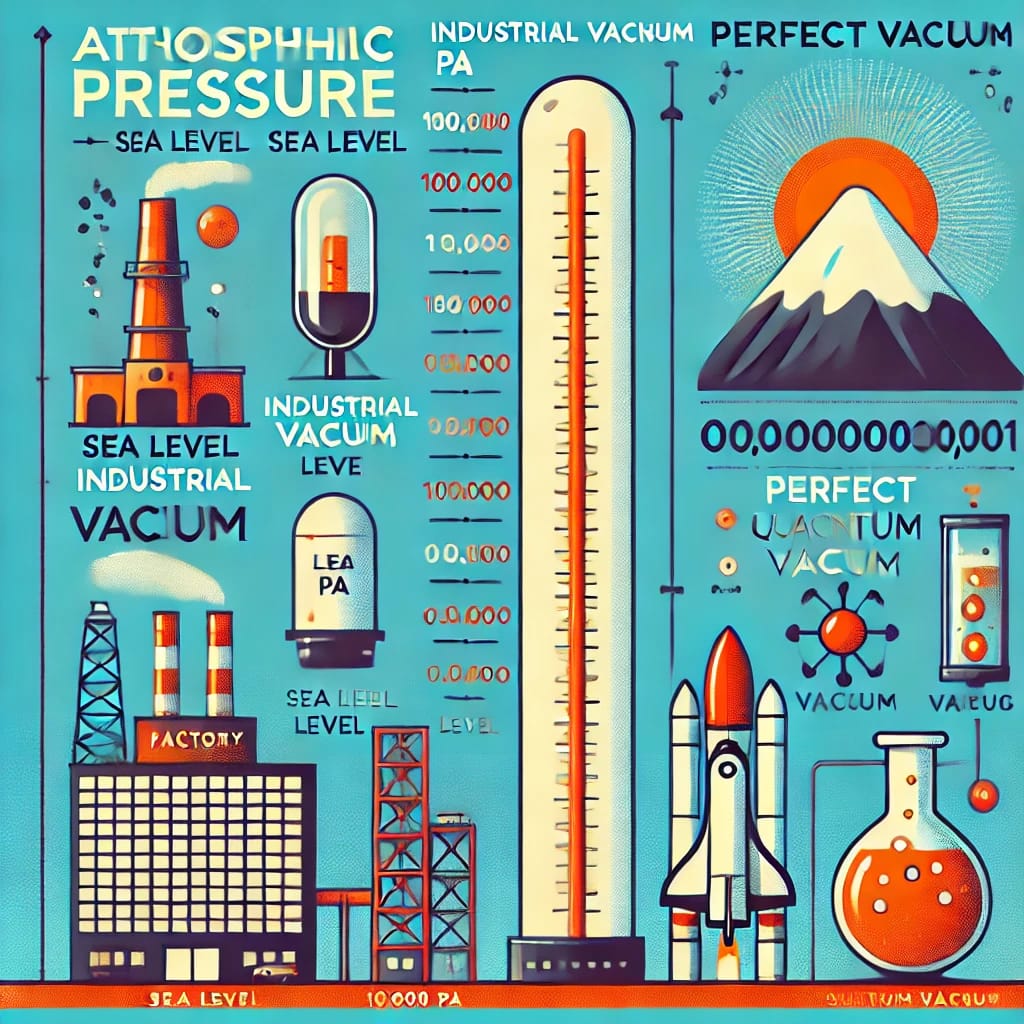

A perfect vacuum represents a space entirely devoid of matter, where pressure theoretically drops to absolute zero. In reality, achieving such a vacuum is impossible due to quantum fluctuations and residual particles. However, high-quality industrial vacuums can approximate this state, creating environments with pressures as low as 10−1310−13 Pascals. In hydraulics, this near-perfect vacuum becomes the driving force, replacing pressurized fluids with controlled negative pressure.

Historical Evolution of Vacuum Technology

The concept of harnessing vacuums dates back to the 17th century with Otto von Guericke’s Magdeburg hemispheres experiment, which demonstrated the power of atmospheric pressure. Over centuries, vacuum technology evolved from rudimentary pumps to sophisticated systems used in particle accelerators and semiconductor manufacturing. The integration of vacuums into hydraulics, however, is a 21st-century innovation, driven by demands for cleaner, safer, and more precise systems.

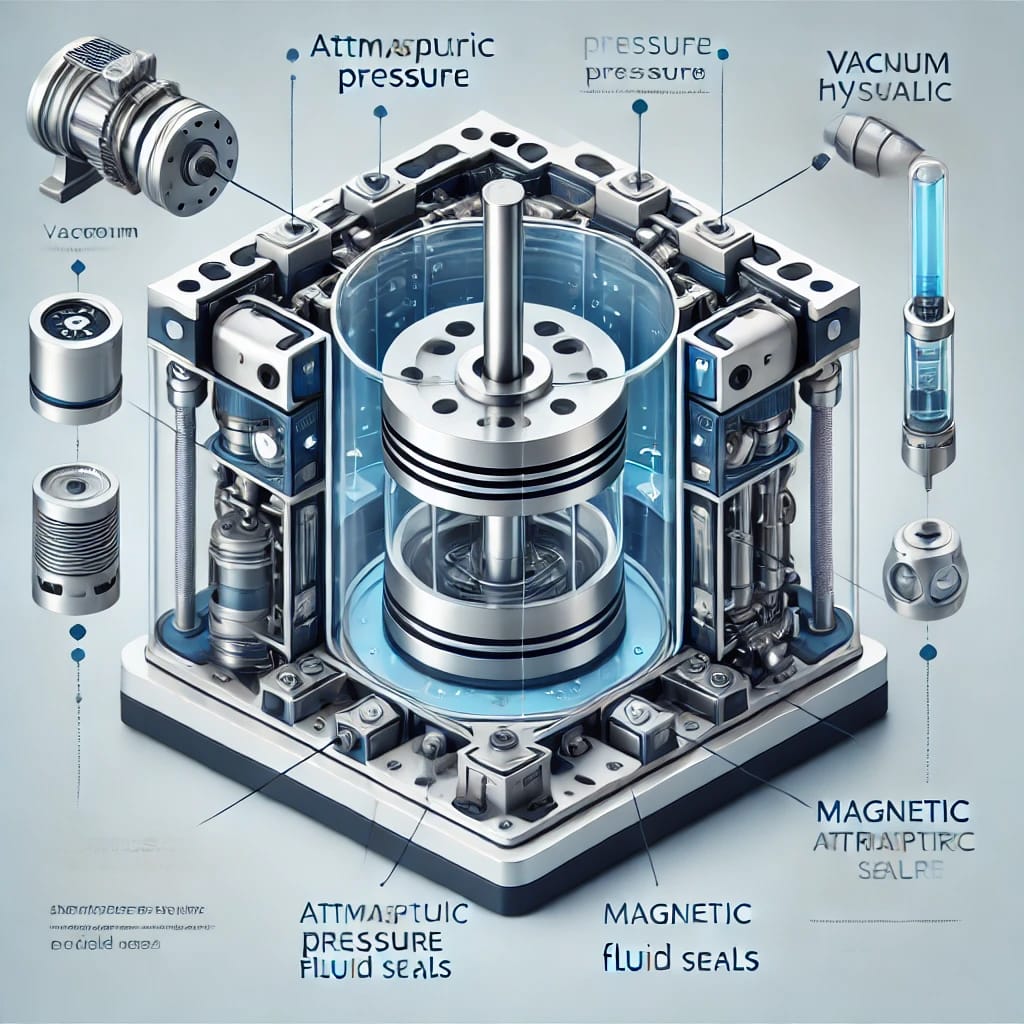

Fundamental Physics

Vacuum hydraulics operates on the principle of pressure differentials. Atmospheric pressure (≈101.325 kPa at sea level) acts on a piston or diaphragm when a vacuum is created on one side. The resulting force (FF) is calculated as:F=(Patm−Pvacuum)×AF=(Patm−Pvacuum)×A

where AA is the actuator’s surface area. As PvacuumPvacuum approaches zero, the force nears Patm×APatm×A, maximizing efficiency.

Key Components and Their Roles

- Vacuum Pumps: Rotary vane, turbomolecular, and cryogenic pumps generate and sustain vacuums. Modern pumps use variable-speed drives to optimize energy use.

- Actuators: Pneumatic cylinders or bellows convert vacuum-induced force into motion. Materials like carbon fiber reduce weight while maintaining structural integrity.

- Seals: Magnetic fluid seals and elastomeric O-rings prevent leaks, critical for maintaining vacuum integrity.

- Control Systems: PID (Proportional-Integral-Derivative) controllers adjust pump speed and valve positions to stabilize pressure dynamically.

Thermodynamic Considerations

Creating a vacuum involves removing gas molecules, which requires energy to overcome entropy. The work (WW) needed to evacuate a volume VV from pressure P1P1 to P2P2 is given by:W=P1Vln(P1P2)W=P1Vln(P2P1)

This equation highlights the exponential energy cost as pressure decreases, a challenge addressed by regenerative energy recovery systems in advanced pumps.

2. Applications of Vacuum Hydraulics

Industrial Automation

In manufacturing, vacuum hydraulics enable precise handling of delicate materials. For example:

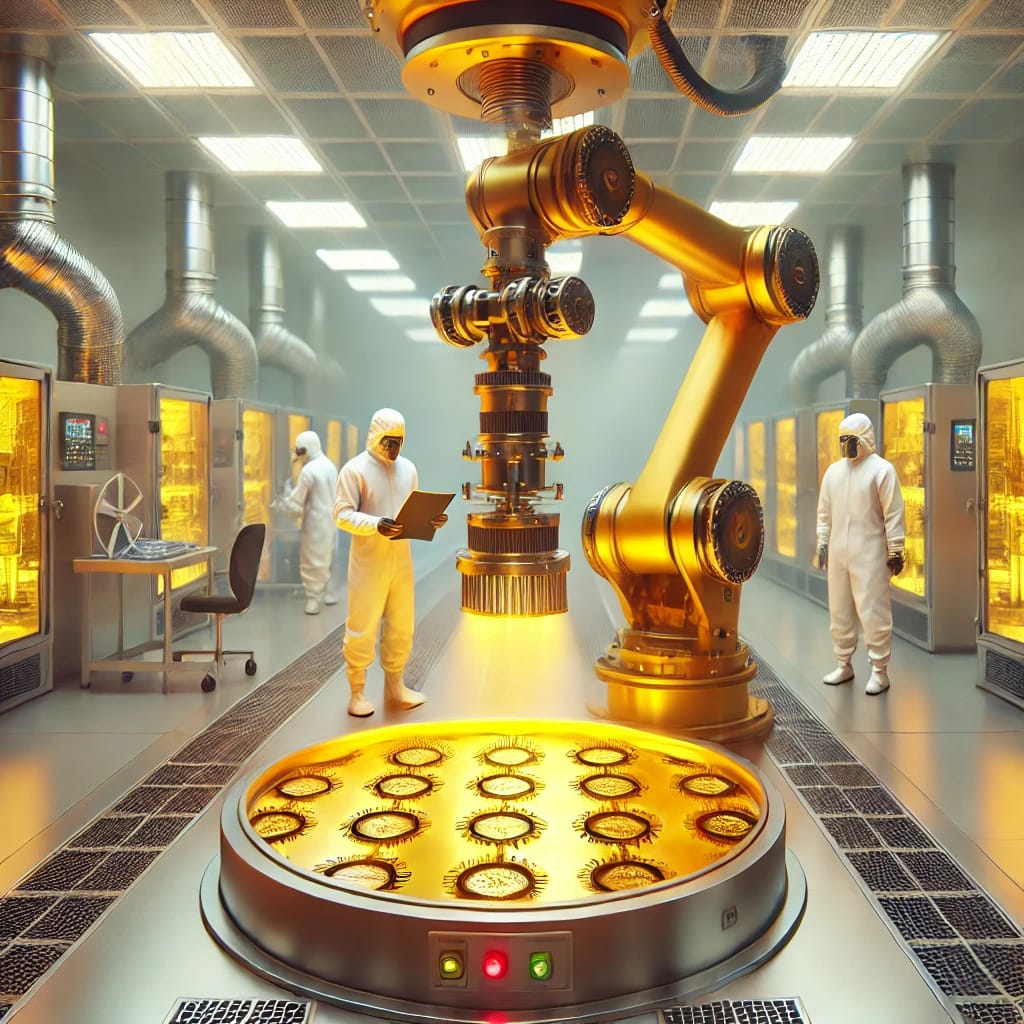

- Semiconductor Fabrication: Robotic arms with vacuum grippers position silicon wafers without contamination. Traditional hydraulics’ fluid leaks could ruin billion-dollar cleanrooms.

- Food Packaging: Vacuum-sealing machines use hydraulics to remove air from packages, extending shelf life while adhering to hygiene standards.

Medical Devices

- Surgical Robots: The da Vinci Surgical System employs vacuum-driven actuators for tremor-free incisions, reducing patient trauma.

- Prosthetics: Lightweight vacuum hydraulics mimic natural muscle movements, offering amputees smoother mobility compared to electric motors.

- Ventilators: Precision vacuum valves adjust airflow in ICU ventilators, critical for patients with acute respiratory distress.

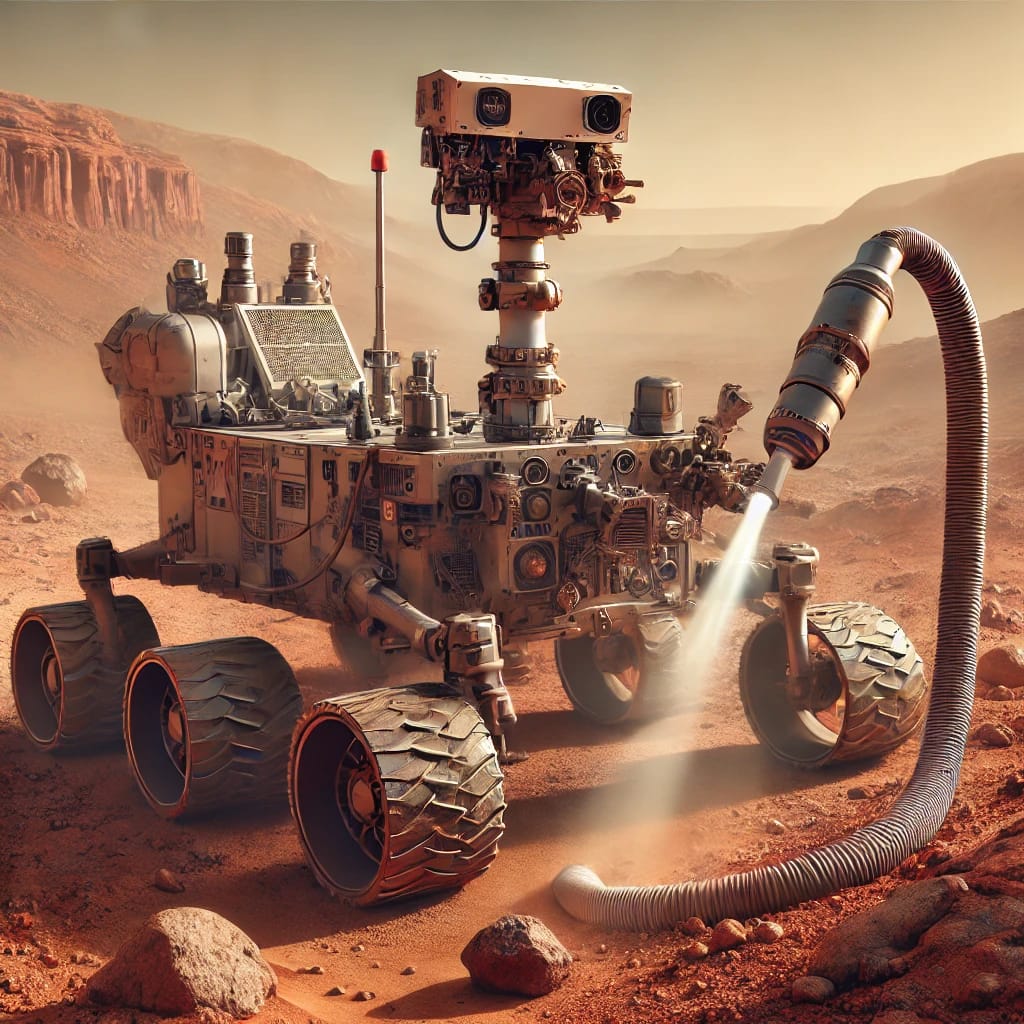

Aerospace and Space Exploration

- Satellite Deployment: Vacuum actuators deploy solar panels in space, where traditional hydraulics would freeze or leak.

- Mars Rovers: NASA’s Perseverance rover uses vacuum systems to handle samples, leveraging Mars’ low ambient pressure (≈0.6 kPa) for efficiency.

Automotive Innovations

- Regenerative Braking: Electric vehicles (EVs) like Tesla’s Cybertruck use vacuum hydraulic brakes that recover kinetic energy, boosting range by 10–15%.

- Active Suspension: Mercedes-Benz’s Magic Body Control employs vacuum-driven dampers to adjust ride height instantaneously, enhancing stability.

Consumer Electronics

- Haptic Feedback: Apple’s Taptic Engine uses micro-scale vacuum actuators to simulate button presses on iPhones, a leap over vibration motors.

- Foldable Screens: Samsung’s Galaxy Fold integrates vacuum hinges to enable seamless folding without mechanical wear.

Emerging Applications

- Soft Robotics: MIT’s “Vacuum-powered Artificial Muscles” (VPAMs) enable octopus-like grippers for underwater exploration.

- Quantum Computing: Ultra-high vacuums (<10−1010−10 Pa) isolate qubits from molecular interference in quantum processors like IBM’s Quantum System Two.

3. Advantages Over Conventional Hydraulics

Safety Enhancements

- Eliminates risks of high-pressure fluid leaks, fires, or explosions.

- Reduces worker exposure to toxic hydraulic oils like polychlorinated biphenyls (PCBs).

Energy Efficiency

- Requires 30–50% less energy than traditional systems, as maintaining a vacuum consumes less power than compressing fluids.

- Regenerative pumps recapture energy during pressure release cycles.

Precision and Control

- Enables micron-level adjustments in microsurgery (e.g., retinal operations) and nanotechnology (e.g., atomic force microscopy).

- Low inertia of vacuum systems allows millisecond response times, critical for aerospace thrust vectoring.

Environmental Sustainability

- Reduces dependency on non-biodegradable hydraulic oils, cutting CO₂ emissions from production and disposal by up to 70%.

- Aligns with EU regulations like REACH (Registration, Evaluation, Authorization of Chemicals) restricting hazardous fluids.

4. Challenges and Limitations

Material and Design Constraints

- Components must withstand 14.7 psi (atmospheric pressure) without collapsing. Solutions include honeycomb-structured alloys and graphene-reinforced composites.

- Thermal management is critical, as gas expansion during vacuum creation can cause temperature swings affecting material stability.

Leakage and Contamination Risks

- Even a 1 µm leak can degrade system performance. Helium leak detection systems, borrowed from nuclear reactor tech, identify breaches with 10−910−9 mbar·L/s sensitivity.

- Particulate contamination from pump oils is mitigated by dry screw pumps or ion-getter pumps in high-vacuum applications.

Scalability Issues

- Scaling for heavy machinery (e.g., excavators) remains challenging due to the need for massive actuators. Hybrid systems combining vacuum and electrohydraulics are under research.

Energy and Cost Barriers

- High-vacuum pumps cost 2–3x more than traditional hydraulic pumps. However, lifecycle savings from reduced maintenance offset initial investments.

- Energy costs for maintaining vacuums in large systems can be prohibitive, though AI-driven predictive algorithms optimize pump usage.

5. The Future of Perfect Vacuum Hydraulics

Smart and Self-Healing Systems

- IoT-enabled actuators with embedded pressure sensors and machine learning algorithms predict failures. For instance, Siemens’ MindSphere platform monitors vacuum integrity in real time.

- Self-sealing materials inspired by biological systems (e.g., blood clotting) automatically repair minor leaks.

Nanotechnology and Biomedical Breakthroughs

- Nanoscale Actuators: ETH Zurich’s “NanoVac” project aims to manipulate DNA strands using vacuum forces, revolutionizing gene editing.

- Targeted Drug Delivery: Vacuum micro-pumps could administer chemotherapy doses directly to tumors, minimizing side effects.

Space Colonization

- On Mars, vacuum hydraulics could power construction robots using the planet’s natural low-pressure environment, reducing Earth-dependent resources.

- Lunar habitats might use vacuum-sealed airlocks and hydraulic mining systems to extract water from regolith.

Quantum Vacuum Innovations

- Theoretical frameworks like the Casimir effect—where quantum fluctuations create measurable forces in a vacuum—could enable frictionless actuators.

- DARPA’s “Vacuum Energy Harvesting” initiative explores extracting energy from quantum vacuum fluctuations, though this remains speculative.

Global Market and Economic Impact

- The vacuum hydraulics market is projected to grow at a CAGR of 8.7% (2023–2030), driven by EV adoption and Industry 4.0.

- Key players include Festo, Parker Hannifin, and Edwards Vacuum, with Asia-Pacific leading due to semiconductor and EV manufacturing hubs.

6. Ethical and Regulatory Considerations

Workforce Training

- Engineers require specialized training in vacuum physics and materials science. Universities like MIT now offer certifications in “Advanced Vacuum Systems Engineering.”

Environmental Regulations

- Compliance with ISO 14001 standards ensures sustainable manufacturing practices for vacuum components.

- Recycling programs for end-of-life vacuum pumps mitigate e-waste challenges.

Conclusion

Perfect vacuum hydraulics represent a paradigm shift in how we harness force, blending theoretical physics with cutting-edge engineering. While challenges persist, the technology’s potential to enhance precision, sustainability, and safety positions it as a cornerstone of future industrial and scientific advancements. As materials science and vacuum technology evolve, systems once deemed impossible may soon become commonplace, reshaping industries from healthcare to interplanetary exploration. The journey toward perfect vacuum hydraulics is not just about creating empty space—it’s about filling it with innovation.

Find More about Vacuum Cleaner:

How should I vacuum my car AC system, which is better: duct cleaning with vacuum or pressure, Best Vacuum Cleaner for Dusting, Which Miele Vacuum to Buy?, Shark vs. Dyson Vacuums: Which Vacuum Brand is Better?, HomePro Handheld Vacuum,